We are delighted to update you on the positive results of the recent INDUSTRONIC workshop with our Polish partner INTROSYS Sp. z o.o. led by our Head of Training & Technical Support Center…

100 V speaker systems have been around for a long time. To call them ‘outdated‘ would be too short-sighted and not really correct.

Let’s take a brief look at the requirements and challenges that need to be met for this type of sound system.

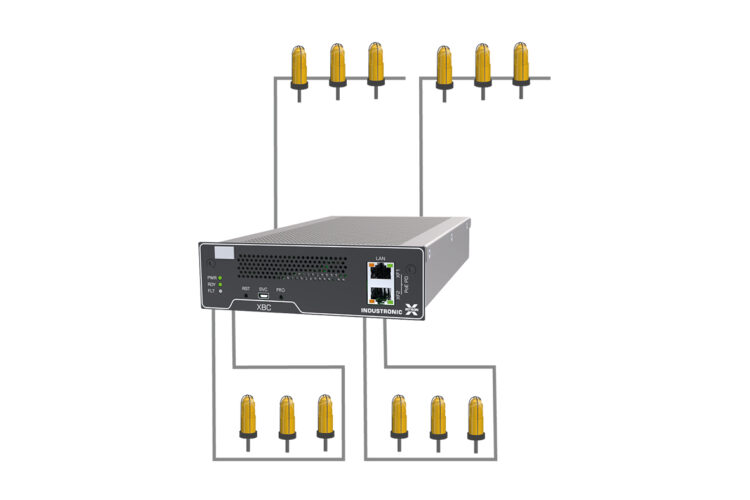

Our XBC is used to switch and monitor up to 4 AC or DC flashing warning beacon circuits wired as line and/or loop.

The XBC supports automatic line monitoring of the flashing warning beacons for cable break, short circuit and ground leakage.

Happy Chinese Lunar New Year to all our friends, colleagues, and customers! As we welcome the Year of the Dragon, we wish you and your loved ones good health, prosperity, and happiness. May this new year bring you success and fulfillment in all your endeavors.

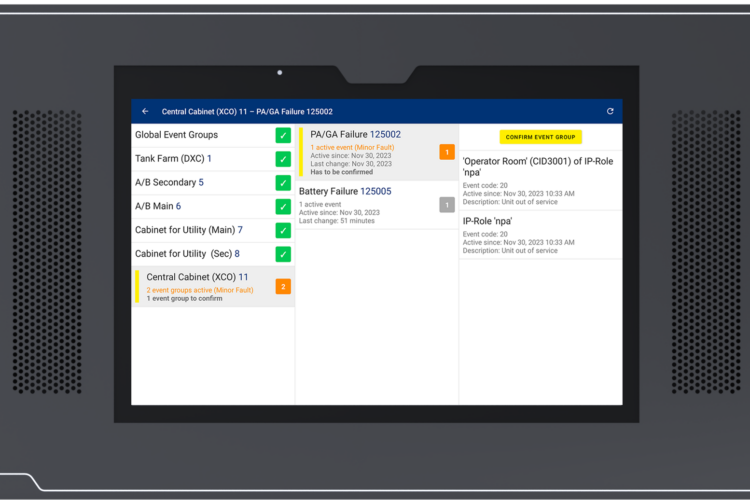

The IP engineering panel NER from INDUSTRONIC is the ideal solution for use as a service intercom station in a cabinet. You can easily access all communication functions via touch screen and an intuitive user interface. Whether you want to use push-to-talk communication, announcements, or alarm triggering, the IP engineering panel offers the same functionality as any other INDUSTRONIC intercom station.

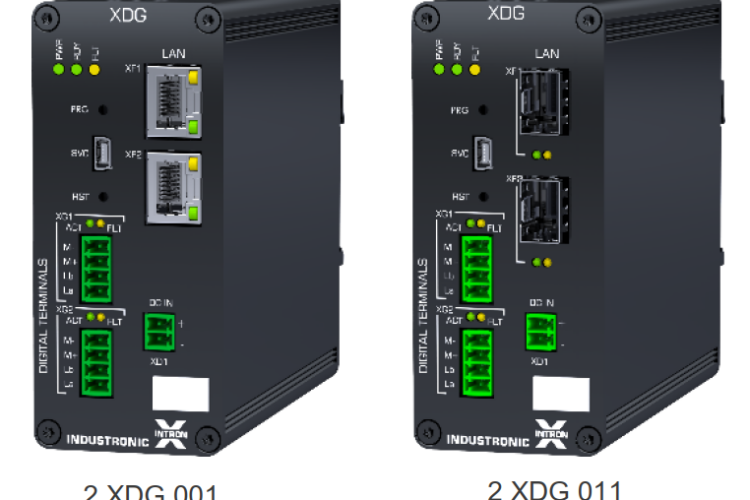

The 2 XDG 0x1 module acts as a network bridge to supply up to two INDUSTRONIC terminal devices with power and data via a 2-/4-wire connection. Both an Ethernet and a fiber-optic version are now available.

Dear readers, For almost 60 years now, INDUSTRONIC has been a successful manufacturer of communication systems for industrial applications in harsh environments. In addition to Oil & Gas, potentially explosive processes for sustainable energy generation such as hydrogen or battery production and recycling are new areas of applications for our systems. Our solutions can also […]

Happy holidays from the entire blog team! As the year comes to a close, we want to…

‘Tis the season to be jolly – on Friday, December 1, almost 160 guests including employees and international attendees from our representative offices and subsidiaries followed the invitation of President Wolfgang Stallmeyer to celebrate together at the venue of the Hotel “Zur Schönen Aussicht” in Marktheidenfeld. The food was delicious and the atmosphere was great. […]

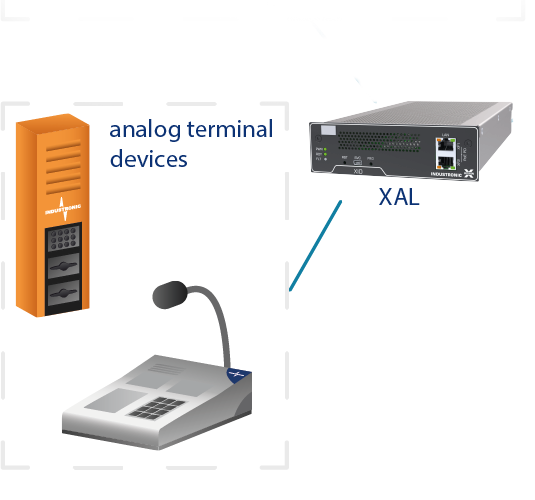

With the XAL module you can connect up to 6 analog audio components – analog intercom stations as well as interconnect INDUSTRONIC systems and third-party systems.